Improving Operational Efficiency: Top Strategies for Manufacturing Success

Understanding Operational Efficiency

In the competitive world of manufacturing, operational efficiency is key to maintaining a successful business. It refers to the ability of a company to deliver products or services in the most cost-effective manner while ensuring the highest quality. By optimizing operations, manufacturers can reduce waste, improve productivity, and ultimately increase profitability.

To achieve operational efficiency, manufacturers must analyze every aspect of their operations and identify areas for improvement. This involves streamlining processes, adopting new technologies, and fostering a culture of continuous improvement. In this blog post, we'll explore several strategies that can help manufacturing businesses boost their operational efficiency.

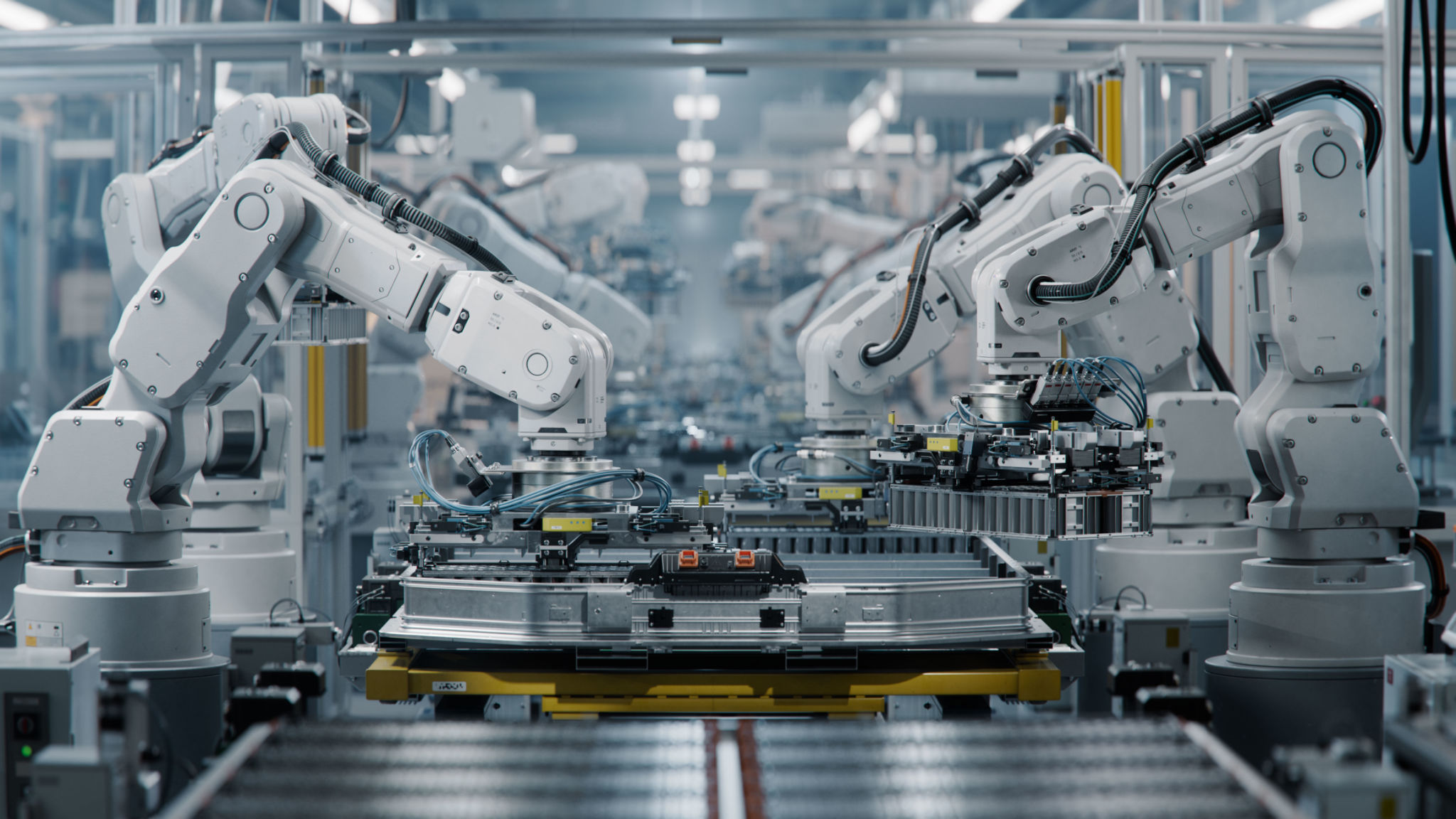

Embrace Automation and Technology

One of the most effective ways to improve operational efficiency is through the use of automation and advanced technologies. Automation can reduce the need for manual labor, minimize errors, and increase production speed. By integrating robotics, AI, and machine learning into manufacturing processes, businesses can achieve greater consistency and precision.

Investing in smart manufacturing technologies such as the Internet of Things (IoT) allows for real-time monitoring and control of production processes. This connectivity ensures that any issues are quickly identified and addressed, minimizing downtime and maximizing output. Additionally, data analytics can provide valuable insights into operational performance, enabling informed decision-making.

Optimize Supply Chain Management

An efficient supply chain is crucial for manufacturing success. By optimizing supply chain management, manufacturers can reduce costs and improve delivery times. This can be achieved through better demand forecasting, inventory management, and supplier collaboration.

Implementing supply chain management software can provide visibility into every stage of the supply chain, from raw material procurement to product delivery. This transparency allows for more accurate planning and coordination, reducing delays and waste. Moreover, building strong relationships with suppliers ensures reliability and can lead to cost-saving opportunities through bulk purchasing or long-term contracts.

Implement Lean Manufacturing Principles

Lean manufacturing focuses on eliminating waste and increasing efficiency. By adopting lean principles, manufacturers can streamline processes and reduce non-value-added activities. This approach involves identifying areas of waste such as overproduction, excess inventory, and unnecessary transportation.

Key lean tools include value stream mapping, continuous flow, and Just-In-Time (JIT) production. These methods help in creating a more efficient workflow, reducing lead times, and improving product quality. Lean manufacturing not only boosts operational efficiency but also enhances customer satisfaction by delivering products faster and more reliably.

Focus on Workforce Training and Engagement

A skilled and motivated workforce is essential for operational efficiency. Providing ongoing training ensures that employees are equipped with the necessary skills to operate advanced machinery and adapt to new technologies. Regular training sessions also foster a culture of continuous improvement and innovation.

Engaging employees in decision-making processes can lead to valuable insights and improvements. Encouraging open communication and feedback creates a collaborative environment where employees feel valued and empowered to contribute to the company's success. Recognizing and rewarding employee achievements further boosts morale and productivity.

Continuous Improvement Through Monitoring and Feedback

Operational efficiency is not a one-time achievement but an ongoing process. Regular monitoring and feedback are essential to identify areas for improvement and ensure that implemented strategies remain effective. Setting clear performance metrics allows businesses to measure progress accurately.

Conducting regular audits and reviews of operations helps in maintaining high standards and identifying potential bottlenecks or inefficiencies. Encouraging a culture of continuous improvement means constantly seeking ways to enhance processes, whether through technological advancements or employee suggestions.