Top Trends in Digital Transformation for the Manufacturing Sector

Embracing Smart Manufacturing

The manufacturing sector is undergoing a significant transformation, driven by the integration of digital technologies. This change, often referred to as Industry 4.0, is reshaping the landscape and creating opportunities for increased efficiency and productivity. As manufacturers navigate this digital evolution, several key trends are emerging that promise to redefine the future of manufacturing.

Internet of Things (IoT) Integration

The Internet of Things is playing a crucial role in digital transformation by connecting devices and systems across the manufacturing floor. IoT enables real-time data collection and analysis, which helps in optimizing processes, reducing downtime, and enhancing predictive maintenance capabilities. Manufacturers are leveraging IoT to gain deeper insights into their operations and make data-driven decisions.

AI and Machine Learning Applications

Artificial intelligence and machine learning are becoming indispensable tools in the manufacturing sector. These technologies facilitate automation and improve quality control by identifying defects or anomalies in production processes. AI-driven analytics provide valuable insights into operational inefficiencies, enabling manufacturers to fine-tune their processes and reduce waste.

Advanced Robotics and Automation

Robots have been a staple in manufacturing for many years, but advancements in robotics technology are now allowing for more sophisticated automation solutions. Collaborative robots, or cobots, work alongside human operators to enhance productivity and safety. These robots are equipped with sensors and machine learning capabilities, enabling them to adapt to different tasks and environments.

Cloud Computing and Data Analytics

Cloud computing is revolutionizing how manufacturers store, process, and analyze data. By moving operations to the cloud, companies can access scalable resources and improve their data management practices. Cloud-based platforms enable seamless collaboration between teams and allow manufacturers to tap into advanced analytics tools that drive strategic decision-making.

Sustainability and Green Manufacturing

As environmental concerns continue to grow, sustainability has become a top priority in the manufacturing sector. Digital transformation is facilitating the shift towards green manufacturing by enabling more efficient resource management and reducing energy consumption. Technologies like digital twins and simulation tools help manufacturers optimize their production processes to minimize environmental impact.

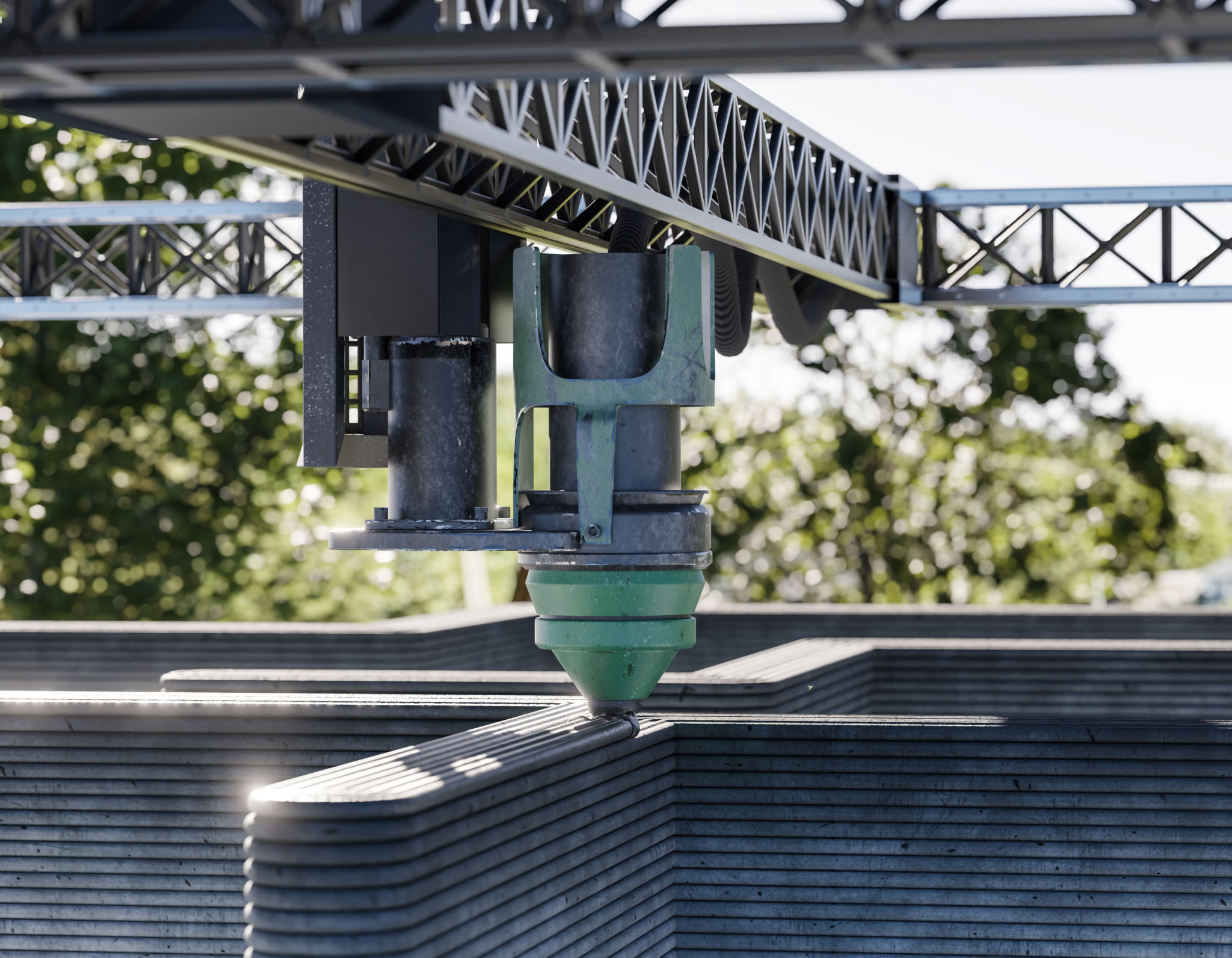

3D Printing and Additive Manufacturing

3D printing is revolutionizing the way products are designed and manufactured. This technology allows for rapid prototyping and customization, reducing lead times and material waste. Additive manufacturing enables manufacturers to produce complex geometries that were previously impossible with traditional methods, opening up new possibilities for innovation.

Cybersecurity Challenges

As manufacturing becomes increasingly digitalized, cybersecurity has emerged as a critical concern. Protecting sensitive data and ensuring the security of connected devices are paramount in preventing disruptions and safeguarding intellectual property. Implementing robust cybersecurity measures is essential for manufacturers to maintain trust with customers and partners.

In conclusion, digital transformation is unlocking immense potential for the manufacturing sector. By embracing these trends, manufacturers can enhance their operations, drive innovation, and remain competitive in an ever-evolving market. As technology continues to advance, staying ahead of these trends will be crucial for sustained success.